Abstract

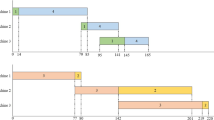

The following work proposes a (max, +) optimization model for scheduling batch transfer operations in a flow network by integrating a cost/criticality criterion to prioritize conflicting operations in terms of resource allocation. The case study is a seaport for oil export where real industrial data has been gathered. The work is extendable to flow networks in general and aims at proposing a general, intuitive algebraic modeling framework through which flow transfer operations can be scheduled based on a criterion that integrates the potential costs due to late client service and critical device reliability in order to satisfy a given set of requests through a set of disjoint alignments in a pipeline network. The research exploits results from previous work and it is suitable for systems handling different client priorities and in which device reliability has an important short-term impact on operations.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Notes

- 1.

a specific scenario is the mixture of two identical oil types. However, oil mixture is not allowed in any scenario since sharing an alignment's section by two transfer operations could result in lower product flow rate and several aspects such as pumping power and pipeline dimensions would have to be considered and are not the focus of this work.

- 2.

taking into consideration that maintenance is not approached in this work.

References

K. Quintero, E. Niel, J. Aguilar et al. (Max, +) Optimization model for scheduling operations in a flow network with preventive maintenance tasks, in Proceedings of The World Congress on Engineering and Computer Science 2013, WCECS 2013. Lecture Notes in Engineering and Computer Science, vol. 2 (San Francisco, USA, 2013), pp. 1036–1041, 23–25 Oct 2013

K. Quintero, E. Niel, J. Aguilar et al., Scheduling operations in a flow network with flexible preventive maintenance: a (max, +) approach. Eng. Lett. 22, 24–33 (2014)

M. Alsaba, J.-L. Boimond, S. Lahaye, On the control of flexible manufacturing production systems by dioid algebra (originally in french: Sur la commande des systèmes flexibles de production manufacturière par l’algèbre des dioïdes). Revue e-STA, Sciences et Technologies de l’Automatique 4, 3247–3259 (2007)

A. Nait-Sidi-Moh, M.-A. Manier, A. El Moudni et al. Petri net with conflicts and (max, +) algebra for transportation systems, in 11th IFAC Symposium on control in transportation systems, 11 pp. 548–553

W. Ait-Cheik-Bihi, A. Nait-Sidi-Moh, M. Wack, Conflict management and resolution using (max, +) algebra: application to services interaction, in Evaluation and Optimization of Innovative Production Systems of Goods and Services: 8th International Conference of Modeling and Simulation—MOSIM’10 (2010)

S.G. Ponnambalam, N. Jawahar, B.S. Girish, An ant colony optimization algorithm for flexible job shop scheduling problem, in New Advanced Technologies (2010), http://www.intechopen.com/books/new-advanced-technologies/An Ant Colony Optimization Algorithm for Flexible Job Shop Scheduling Problem. Accessed 11 Feb 2014

W. Moore, A. Starr, An intelligent maintenance system for continuous cost-based prioritization of maintenance activities. Computers in industry (2006), doi:10.1016/j.compind.2006.02.008

K. Yang, X. Liu, A bi-criteria optimization model and algorithm for scheduling in a real-world flow shop with setup times, in Proceedings of the International Conference on Intelligent Computation Technology and Automation (ICICTA), vol.1, (2008), pp. 535–539

Z. Zhao, G. Zhang, Z. Bing, Job-shop scheduling optimization design based on an improved GA, in Proceedings of the 10th World Congress on Intelligent Control and Automation (WCICA), 2012, pp. 654–659

C. Zeng, J. Tang, H. Zhu, Two heuristic algorithms of job scheduling problem with inter-cell production mode in hybrid operations of machining, in 25th Chinese Control and Decision Conference (CCDC), 2013, pp. 1281–1285

J. Rojas-D’Onofrio, J. González, E. Boutleux et al. Path search algorithm minimizing interferences with envisaged operations in a pipe network, in Proceedings of the European Control Conference, ECC’09 (2009)

K. Quintero, E. Niel, J. Rojas-D’Onofrio, Optimizing process supervision in a flow network in terms of operative capacity and failure risk, in 15th International congress on automation, systems and instrumentation, 2011

F. Baccelli, G. Cohen, G. Jan-Olsder, J.-P. Quadrat, Synchronization and Linearity an Algebra for Discrete Event Systems. (Wiley, New York, 2001)

G. Cohen, S. Gaubert, J.-P. Quadrat, Sandwich algebra (originally in french: lalg`ebre des sandwichs). Pour la science 328, 56–63 (2005)

L. Houssin, S. Lahaye, J.-L. Boimond, Just-in-time control under constraints of (max, +)-linear systems (originally in french: Commande en juste-à-temps sous contraintes de systèmes (max, +)-linéaires). Journal Européen des systèmes automatisés—JESA 39, 335–350 (2005)

G. Nasri I, Habchi, R. Boukezzoula, An algebraic max-plus model for HVLV systems scheduling and optimization with repetitive and flexible periodic preventive maintenance: just-in-time production, in 9th International Conference of Modeling, Optimization and Simulation—MOSIM’12, 2012

Z. Königsberg, Modeling, analysis and timetable design of a helicopter maintenance process based on timed event petri nets and max-plus algebra. Neural Parallel Sci Comput. 18, 1–12 (2010)

S. Gaubert, Performance evaluation of (max, +) automata. IEEE Trans. Autom. Control 40, 2014–2025 (1995)

S. Lahaye, J. Komenda, J.-L. Boimond, Modular modeling with (max, +) automata (originally in french: Modélisation modulaire à l’aide d’automates (max, +)), in Conférence internationale francophone d’automatique—CIFA. (Grenoble, France 2012)

J. Komenda, S. Lahaye, J.-L. Boimond, The synchronous product of (max, +) automata (originally in french: Le produit synchrone des automates (max, +)). Special issue of Journal Européen des Systèmes Automatisés—JESA 43, 1033–1047 (2009)

Acknowledgments

This research has been supported by Thales Group France, and by the PCP (Post-graduate Cooperation Program) between Venezuela and France involving the collaboration between the academic institutions: ULA (in Spanish: Universidad de Los Andes)—research laboratory: CEMISID in Mérida, Venezuela and the INSA (in French: Université de Lyon, INSA Lyon, Ampère (UMR5005)) in Lyon, France; and the industrial partners Thales Group France and PDVSA (in Spanish: Petróleos de Venezuela Sociedad Anónima), the Venezuelan oil company. Industrial data for model validation has been granted by PDVSA.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer Science+Business Media Dordrecht

About this paper

Cite this paper

Quintero, K., Niel, E., Aguilar, J., Piétrac, L. (2014). A Cost-Criticality Based (Max, +) Optimization Model for Operations Scheduling. In: Kim, H., Ao, SI., Amouzegar, M. (eds) Transactions on Engineering Technologies. Springer, Dordrecht. https://doi.org/10.1007/978-94-017-9115-1_47

Download citation

DOI: https://doi.org/10.1007/978-94-017-9115-1_47

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-017-9114-4

Online ISBN: 978-94-017-9115-1

eBook Packages: EngineeringEngineering (R0)