Abstract

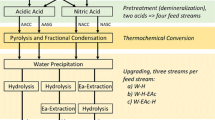

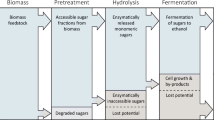

In order to enable the large-scale production of biofuels or chemicals from lignocellulosic biomass, a consistent and affordable year-round supply of lignocellulosic feedstocks is essential. Feedstock blending and/or densification offers one promising solution to overcome current challenges on biomass supply, i.e., low energy and bulk densities and significant compositional variations. Therefore, it is imperative to develop conversion technologies that can process mixed pelleted biomass feedstocks with minimal negative impact in terms of overall performance of the relevant biorefinery unit operations: pretreatment, fermentable sugar production, and fuel titers. We processed the mixture of four feedstocks—corn stover, switchgrass, lodgepole pine, and eucalyptus (1:1:1:1 on dry weight basis)—in flour and pellet form using ionic liquid (IL) 1-ethyl-3-methylimidazolium acetate, dilute sulfuric acid (DA), and soaking in aqueous ammonia (SAA) pretreatments. Commercial enzyme mixtures, including cellulases and hemicellulases, were then applied to these pretreated feedstocks at low to moderate enzyme loadings to determine hydrolysis efficiency. Results show significant variations on the chemical composition, crystallinity, and enzymatic digestibility of the pretreated feedstocks across the different pretreatment technologies studied. The advanced biofuel isopentenol was produced during simultaneous saccharification and fermentation (SSF) of pretreated feedstocks using an engineered Escherichia coli strain. Results show that IL pretreatment liberates the most sugar during enzymatic saccharification, and in turn led to the highest isopentenol titer as compared to DA and SAA pretreatments. This study provides insights on developing biorefinery technologies that produce advanced biofuels based on mixed feedstock streams.

Similar content being viewed by others

References

Richard TL (2010) Challenges in Scaling Up Biofuels Infrastructure. Science 329(5993):793–796. doi:10.1126/science.1189139

Milbrandt A (2005) A geographic perspective on the current biomass resource availability in the United States. Technical Report: NREL/TP-560-39181

Tumuluru JS, Wright CT, Hess JR, Kenney KL (2011) A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioproducts Biorefining Bioprod 5(6):683–707. doi:10.1002/Bbb.324

Mani S, Tabil LG, Sokhansanj S (2006) Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 30(7):648–654. doi:10.1016/j.biombioe.2005.01.004

Theerarattananoon K, Xu F, Wilson J, Staggenborg S, Mckinney L, Vadlani P, Pei Z, Wang D (2012) Effects of the pelleting conditions on chemical composition and sugar yield of corn stover, big bluestem, wheat straw, and sorghum stalk pellets. Bioprocess Biosyst Eng 35(4):615–623

Ray AE, Hoover AN, Nagle N, Chen X, Gresham GL (2013) Effect of pelleting on the recalcitrance and bioconversion of dilute-acid pretreated corn stover under low-and high-solids conditions. Biofuels 4(3):271–284

Pirraglia A, Gonzalez R, Saloni D (2010) Techno-Economical Analysis of Wood Pellets Production for Us Manufacturers. Bioresources 5(4):2374–2390

Jacobson JJ, Carnohan S, Ford A, Beall A (2014) Simulating Pelletization Strategies to Reduce the Biomass Supply Risk at America’s Biorefineries. Paper presented at the 2014 International System Dynamics Conference

Iroba KL, Tabil LG, Sokhansanj S, Meda V (2014) Producing durable pellets from barley straw subjected to radio frequency-alkaline and steam explosion pretreatments. Int J Agric Biol Eng 7(3):68–82. doi:10.3965/j.ijabe.20140703.009

Rijal B, Igathinathane C, Karki B, Yu M, Pryor SW (2012) Combined effect of pelleting and pretreatment on enzymatic hydrolysis of switchgrass. Bioresour Technol 116:36–41. doi:10.1016/j.biortech.2012.04.054

Stelte W, Sanadi AR, Shang L, Holm JK, Ahrenfeldt J, Henriksen UB (2012) Recent Developments in Biomass Pelletization - a Review. Bioresources 7(3):4451–4490

Tooyserkani Z, Kumar L, Sokhansanj S, Saddler J, Bi XTT, Lim CJ, Lau A, Melin S (2013) SO2-catalyzed steam pretreatment enhances the strength and stability of softwood pellets. Bioresour Technol 130:59–68. doi:10.1016/j.biortech.2012.12.004

Nahar N, Pryor SW (2014) Reduced pretreatment severity and enzyme loading enabled through switchgrass pelleting. Biomass Bioenergy 67:46–52. doi:10.1016/j.biombioe.2014.04.027

Shi J, Thompson VS, Yancey NA, Stavila V, Simmons BA, Singh S (2013) Impact of mixed feedstocks and feedstock densification on ionic liquid pretreatment efficiency. Biofuels 4(1):63–72

Guragain YN, Wilson J, Staggenborg S, McKinney L, Wang DH, Vadlani PV (2013) Evaluation of pelleting as a pre-processing step for effective biomass deconstruction and fermentation. Biochem Eng J 77:198–207. doi:10.1016/j.bej.2013.05.014

Rijal B, Biersbach G, Gibbons WR, Pryor SW (2014) Effect of Initial Particle Size and Densification on AFEX-Pretreated Biomass for Ethanol Production. Appl Biochem Biotechnol 174(2):845–854. doi:10.1007/s12010-014-1120-y

ASTM (2012) Standard test method for sampling granular carriers and granular pesticides. vol ASTM E725-96. doi:10.1520/E0725-96R12

Selig M, Weiss N, Ji Y (2008) Enzymatic Saccharification of Lignocellulosic Biomass.Technical Report: NREL/TP-510-42629; Golden, CO, 2008

Sluiter JB, Ruiz RO, Scarlata CJ, Sluiter AD, Templeton DW (2010) Compositional Analysis of Lignocellulosic Feedstocks. 1. Review and Description of Methods. J Agric Food Chem 58(16):9043–9053. doi:10.1021/Jf1008023

Singh S, Simmons BA, Vogel KP (2009) Visualization of Biomass Solubilization and Cellulose Regeneration During Ionic Liquid Pretreatment of Switchgrass. Biotechnol Bioeng 104(1):68–75. doi:10.1002/Bit.22386

George KW, Chen A, Jain A, Batth TS, Baidoo EEK, Wang G, Adams PD, Petzold CJ, Keasling JD, Lee TS (2014) Correlation analysis of targeted proteins and metabolites to assess and engineer microbial isopentenol production. Biotechnol Bioeng. doi:10.1002/bit.25226

Chou HH, Keasling JD (2012) Synthetic Pathway for Production of Five-Carbon Alcohols from Isopentenyl Diphosphate. Appl Environ Microbiol 78(22):7849–7855. doi:10.1128/Aem. 01175-12

DOE (2012) 2011 Platform Review Report An Independent Evaluation of Platform Activities for FY 2010 and FY 2011. Washington DC

Wyman CE, Balan V, Dale BE, Elander RT, Falls M, Hames B, Holtzapple MT, Ladisch MR, Lee YY, Mosier N, Pallapolu VR, Shi J, Thomas SR, Warner RE (2011) Comparative data on effects of leading pretreatments and enzyme loadings and formulations on sugar yields from different switchgrass sources. Bioresour Technol 102(24):11052–11062. doi:10.1016/j.biortech.2011.06.069

Kumar R, Mago G, Balan V, Wyman CE (2009) Physical and chemical characterizations of corn stover and poplar solids resulting from leading pretreatment technologies. Bioresour Technol 100(17):3948–3962. doi:10.1016/j.biortech.2009.01.075

Li C, Sun L, Simmons BA, Singh S (2013) Comparing the Recalcitrance of Eucalyptus, Pine, and Switchgrass Using Ionic Liquid and Dilute Acid Pretreatments. BioEnergy Res 6(1):14–23

Shi J, Ebrik MA, Wyman CE (2011) Sugar yields from dilute sulfuric acid and sulfur dioxide pretreatments and subsequent enzymatic hydrolysis of switchgrass. Bioresour Technol 102(19):8930–8938. doi:10.1016/j.biortech.2011.07.042

Lloyd TA, Wyman CE (2005) Combined sugar yields for dilute sulfuric acid pretreatment of corn stover followed by enzymatic hydrolysis of the remaining solids. Bioresour Technol 96(18):1967–1977

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnology for Biofuels 3. doi:10.1186/1754-6834-3-10

O'Sullivan AC (1997) Cellulose: the structure slowly unravels. Cellulose 4(3):173–207

Kim TH, Taylor F, Hicks KB (2008) Bioethanol production from barley hull using SAA (soaking in aqueous ammonia) pretreatment. Bioresour Technol 99(13):5694–5702. doi:10.1016/j.biortech.2007.10.055

Kim TH, Kim JS, Sunwoo C, Lee Y (2003) Pretreatment of corn stover by aqueous ammonia. Bioresour Technol 90(1):39–47

Li CL, Knierim B, Manisseri C, Arora R, Scheller HV, Auer M, Vogel KP, Simmons BA, Singh S (2010) Comparison of dilute acid and ionic liquid pretreatment of switchgrass: Biomass recalcitrance, delignification and enzymatic saccharification. Bioresour Technol 101(13):4900–4906. doi:10.1016/j.biortech.2009.10.066

Zhang T, Wyman CE, Jakob K, Yang B (2012) Rapid selection and identification of Miscanthus genotypes with enhanced glucan and xylan yields from hydrothermal pretreatment followed by enzymatic hydrolysis. Biotechnol Biofuels 5:56

Shi J, Ebrik MA, Yang B, Garlock RJ, Balan V, Dale BE, Pallapolu VR, Lee YY, Kim Y, Mosier NS, Ladisch MR, Holtzapple MT, Falls M, Sierra-Ramirez R, Donohoe BS, Vinzant TB, Elander RT, Hames B, Thomas S, Warner RE, Wyman CE (2011) Application of cellulase and hemicellulase to pure xylan, pure cellulose, and switchgrass solids from leading pretreatments. Bioresour Technol 102(24):11080–11088. doi:10.1016/j.biortech.2011.04.003

Wyman CE, Dale BE, Balan V, Elander RT, Holtzapple MT, Ramirez RS, Ladisch MR, Mosier NS, Lee YY, Gupta R, Thomas SR, Hames BR, R. W, R. K (2013) Comparative Performance of Leading Pretreatment Technologies for Biological Conversion of Corn Stover, Poplar Wood, and Switchgrass to Sugars. In: Wyman CE (ed). doi:10.1002/9780470975831

Olofsson K, Bertilsson M, Lidén G (2008) A short review on SSF-an interesting process option for ethanol production from lignocellulosic feedstocks. Biotechnol Biofuels 1(7):1–14

Brethauer S, Wyman CE (2010) Review: continuous hydrolysis and fermentation for cellulosic ethanol production. Bioresour Technol 101(13):4862–4874

Acknowledgments

This work conducted by the Joint BioEnergy Institute was supported by the Office of Science, Office of Biological and Environmental Research, of the US Department of Energy under Contract No. DE-AC02-05CH11231. ABPDU acknowledges the funding support from Office of Biomass Program within the US DOE’s Office of Energy Efficiency and Renewable Energy, and also the funding support from the American Recovery and Reinvestment Act. We acknowledge Vicki S. Thompson and Neal A. Yancey from Idaho National Laboratory for providing biomass feedstocks and Sonny Zhang for lab assistance. We thank Novozymes for the gift of the enzyme mixtures used in this study.

Conflict of Interest

The authors claim no competing interests.

Authors’ Contributions

JS, KG, and NS conducted pretreatment, saccharification, and fermentation experiments. JS and KG conducted data analysis and drafted the manuscript. WH and CL carried out the calorimetric measurements while VS performed pXRD. SS, TSL, JDK, and BAS coordinated and supervised the research and collaborative efforts. All authors read and approved the final manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, J., George, K.W., Sun, N. et al. Impact of Pretreatment Technologies on Saccharification and Isopentenol Fermentation of Mixed Lignocellulosic Feedstocks. Bioenerg. Res. 8, 1004–1013 (2015). https://doi.org/10.1007/s12155-015-9588-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-015-9588-z